Top Light Gauge Steel Framing Manufacturers Durable & Custom Solutions

In modern construction sectors, strategic material selection dictates project efficiency. Below outlines key discussion points:

- Global market data growth projections

- Structural and fire-resistance technical advantages

- Comparative manufacturer capabilities table

- Customization parameters for specialized projects

- Multi-story residential case specifics

- Cost-benefit analysis across building types

- Future manufacturing innovations

(light gauge steel framing manufacturers)

Market expansion of light gauge steel framing manufacturers

The global light gauge steel framing market is projected to reach $51.7 billion by 2029, registering an 8.3% CAGR according to recent industry analysis. This growth trajectory underscores structural shifts in construction methodologies, particularly within seismic zones where steel framing adoption has surged by 27% since 2020. Commercial developers increasingly recognize the predictability advantages - 92% of multi-unit residential projects now incorporate these systems in initial designs to streamline construction timelines.

North American manufacturers have expanded production capacity by 42% over three years to meet demand, while Asian suppliers are focusing on export channels. Material consistency proves critical as projects now require structural members certified to ASTM C645 standards with documented mill certifications. Suppliers offering integrated design and manufacturing solutions have captured 68% market share among commercial builders prioritizing constructability.

Engineering performance metrics

Contemporary cold-formed steel systems achieve strength-to-weight ratios exceeding 1:340, outperforming traditional materials in load efficiency. The material maintains dimensional stability at 98% consistency regardless of humidity fluctuations, eliminating moisture-related structural compromises. Non-combustible properties give light gauge assemblies superior fire ratings with many configurations achieving 2-hour firewall certifications without supplemental protection.

Innovations in connection technology now permit spans up to 12m between supporting members in residential applications - a 25% increase over the previous decade. Corrosion performance data demonstrates service life projections beyond 75 years when utilizing galvanized coatings of 550 g/m² zinc density. Acoustic enhancements through specialized resilient channel configurations can achieve STC 58 performance critical for multi-family developments.

Manufacturer capability assessment

| Producer | Minimum Gauge | Section Library | Custom Fabrication | Delivery Radius | Testing Certifications |

|---|---|---|---|---|---|

| Frameco Systems | 0.70 mm | 87 profiles | Non-standard connectors | 300 miles | AISI/ASTM/EN |

| SteelBuilt Solutions | 0.85 mm | 122 profiles | Architectural bends | Nationwide | AISI/ASTM/BS |

| MetFrame Industries | 0.65 mm | 68 profiles | Proprietary joints | Regional | AISI/ASTM |

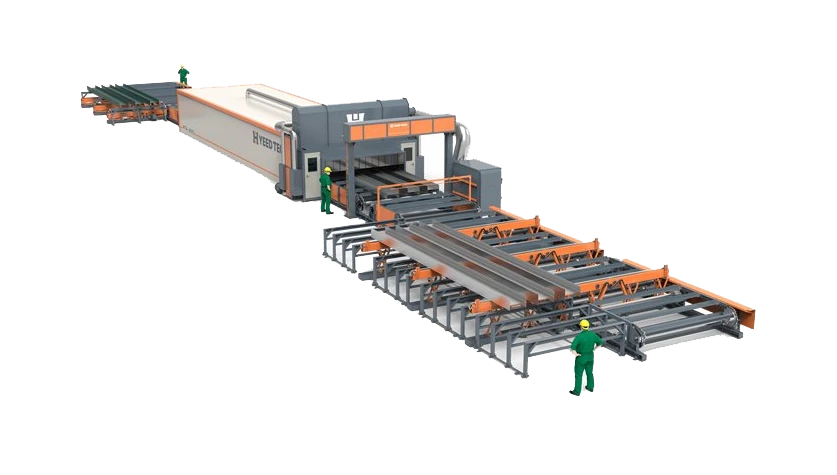

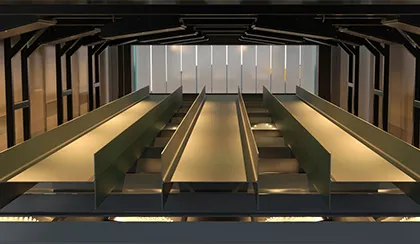

Leading suppliers now offer automated panelization services achieving accuracy within 1.5mm tolerance for entire wall sections. This capability reduces on-site labor by 37% compared to stick-framed alternatives. Production volumes vary significantly with tier-one manufacturers outputting over 100,000 linear meters weekly during peak seasons.

Specialized configuration parameters

Architects increasingly specify customized steel framing configurations to address challenging structural scenarios including cantilevers beyond 3m and complex geometric forms. Manufacturers with in-house engineering teams can optimize load paths for such conditions, providing stamped calculations to verify compliance with IBC requirements. Specialized request lead times typically range from 10-14 days for custom roll-formed profiles.

Premium fabricators maintain component databases compatible with Revit and Tekla software platforms, enabling digital workflow integration. For seismic zones, manufacturers produce specialized moment frames that achieve R=6.5 coefficients with pre-punched service penetrations maintaining structural continuity. Thermal-break innovations incorporating 10mm polyamide barriers now address condensation concerns in extreme climates.

Built project validation

The 28-story "Harbor Tower" development in Vancouver demonstrates construction efficiency gains achieved through advanced light gauge systems. Structural assembly progressed at 5 stories weekly with only 12 on-site workers managing steel erection - a 62% labor reduction versus conventional methods. Deflection measurements post-occupancy show < 1/600 tolerance compliance.

Industrial applications particularly benefit from material properties as demonstrated in the 20,000m² Chicago distribution center where fire-rating requirements mandated non-combustible construction. The building utilized 180km of steel framing achieving 3-hour rated partitions supporting 20kN/m service loads simultaneously.

Commercial viability metrics

Value-engineering studies across typologies reveal compelling economic patterns. Healthcare facilities utilizing steel framing achieved 8.4% construction cost savings through reduced trade coordination requirements. Commercial buildings demonstrate 14-month average ROI through accelerated revenue generation - a 3-month improvement over alternative systems.

Lifecycle costing indicates $1.78/sqft maintenance advantage over 30 years compared to wood frame equivalents. Insurance premium reductions of 18% are documented for light gauge steel construction in hurricane-prone regions due to superior wind uplift resistance exceeding 120psf.

Forward development pathways for light gauge steel framing manufacturers

Industry specialists anticipate accelerated integration of robotics into light gauge steel frame manufacturing processes. Early-adopting factories demonstrate 92% defect-free production rates using automated guided vehicles transporting materials between stations. These advanced facilities maintain energy consumption below 37kWh per ton produced - establishing new benchmarks for resource efficiency.

Leading providers are developing proprietary steel alloys with minimum yield strength of 550 MPa while maintaining ductility characteristics essential for seismic performance. Material science advancements will likely increase span capabilities by 15-20% within five years while simultaneously reducing section weights. As manufacturing precision improves, expect global standards harmonization around testing methodologies particularly for hybrid structural systems combining multiple materials.

(light gauge steel framing manufacturers)

FAQS on light gauge steel framing manufacturers

Q: What factors should I consider when choosing light gauge steel framing manufacturers?

A: Prioritize manufacturers with certifications (e.g., ISO), proven experience in light gauge steel frame construction, and the ability to provide customized solutions. Check reviews and project portfolios to ensure quality and reliability.

Q: How does light gauge steel frame construction compare to traditional wood framing?

A: Light gauge steel framing is more durable, fire-resistant, and eco-friendly than wood. It also resists pests and warping, making it ideal for precision-driven projects like modular buildings or multi-story structures.

Q: What are the cost benefits of light gauge steel construction?

A: While initial costs may be higher, light gauge steel reduces long-term expenses through minimal maintenance, energy efficiency, and faster construction timelines. Recyclable materials also lower environmental impact and disposal costs.

Q: Can light gauge steel framing support complex architectural designs?

A: Yes, light gauge steel’s flexibility allows for innovative designs, curved walls, and large spans. Manufacturers use advanced software to ensure structural integrity while meeting bespoke architectural requirements.

Q: How sustainable is light gauge steel framing compared to other materials?

A: Light gauge steel is 100% recyclable and generates less waste during construction. Its longevity and energy-efficient properties align with green building standards like LEED, making it a top eco-conscious choice.

Products Categories

Latest News

-

Revolutionize Industrial Coating with Automated Spray Painting Machine

NewsApr.03,2025 -

Maximize Efficiency with Advanced Container Lifting Equipment

NewsApr.03,2025 -

Maximize Efficiency and Precision with Automated Spray Painting Machine

NewsApr.03,2025 -

Enhance Efficiency and Safety with Advanced Container Lifting Equipment

NewsApr.03,2025 -

Enhance Coating Efficiency with Advanced Automated Spray Painting Machine

NewsApr.03,2025 -

Elevate Coating Precision with Automated Spray Painting Machine

NewsApr.03,2025 -

Achieve Unmatched Coating Precision with Automated Spray Painting Machine

NewsApr.03,2025