High-Strength IPE Beams Metal Guard Rails & Hollow Steel Beams

- The Fundamental Role of Structural Beams in Infrastructure

- Market Data: Growth Projections for Beam Systems

- Engineering Advantages of Modern Beam Solutions

- Manufacturer Comparison: Performance Metrics Analysis

- Custom Fabrication Processes for Specialized Projects

- Implementation Case Studies Across Industries

- Future-Proofing Structures with IPE Beam Systems

(ipe beam)

Understanding IPE Beam Fundamentals in Structural Engineering

IPE beams, designated by the European standard I-shaped Parallel Flange profiles, form the backbone of modern structural systems. These hot-rolled steel sections feature parallel flange surfaces and constant web thickness, delivering exceptional load distribution properties. Unlike conventional I-beams, the IPE classification follows metric dimensions that enable more precise engineering calculations. When paired with complementary systems like metal beam guard rail protection, these components create comprehensive safety solutions for transportation infrastructure. Their inherent rigidity makes them particularly suitable for bridges, industrial platforms, and high-stress architectural applications where deflection control is critical.

Market Analysis and Material Impact Data

The global structural steel beam market demonstrates robust growth, with projections indicating a 5.7% CAGR through 2028 according to recent industry analysis. This expansion correlates directly with infrastructure development spending, which exceeded $1.2 trillion worldwide last year. Performance data reveals compelling advantages of steel systems: a typical hollow steel beam installation provides 35% faster assembly than concrete alternatives while offering 18% better seismic resilience. Guard rail impact tests show that properly installed metal beam guard rail systems absorb up to 85% of collision energy before reaching critical deformation thresholds. These quantitative benefits drive increasing specification of steel solutions for government tenders and commercial developments.

Technical Advantages in Structural Applications

Modern steel beam systems provide distinct engineering benefits impossible to achieve with alternative materials. The open-web configuration of certain hollow steel beam designs permits mechanical and electrical services integration, reducing ceiling heights by up to 20%. Corrosion resistance has been significantly enhanced through metallurgical advancements; contemporary IPE beam treatments demonstrate 5,000-hour salt spray resistance without degradation. The characteristic geometry of metal beam guard rail installations delivers controlled deformation behavior during impacts, reducing vehicle deceleration forces by approximately 40% compared to rigid barriers. This combines with seismic performance advantages where high-grade steel systems withstand 25% greater deflection angles before failure.

Manufacturer Performance Comparison

| Specification | Standard IPE Beam | Premium Reinforced IPE | Hollow Steel Alternative |

|---|---|---|---|

| Yield Strength (MPa) | 275-355 | 420-550 | 345-415 |

| Weight Efficiency (m span/kg) | 1:48 | 1:63 | 1:41 |

| Corrosion Resistance Rating | ASTM B117: 2,000h | ASTM B117: 5,000h | ASTM B117: 3,200h |

| Guard Rail Impact Rating | MASH TL-2 | MASH TL-3 | MASH TL-3 |

| Production Lead Time (weeks) | 2-3 | 4-5 | 3-4 |

Custom Fabrication Methodologies

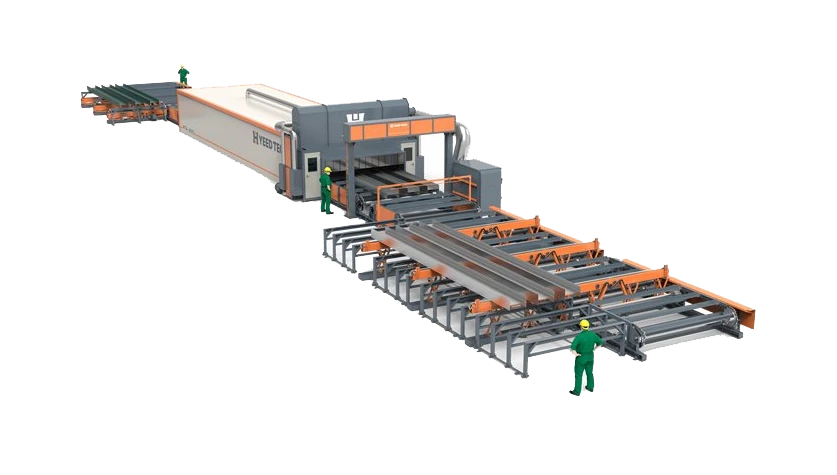

Specialized projects increasingly require customized beam solutions produced through advanced fabrication techniques. Using CNC plasma cutting systems allows for complex penetrations in hollow steel beam profiles with dimensional tolerances below ±0.8mm. Curved IPE beam configurations with radii down to 18 meters are achievable through computer-controlled incremental bending processes. For specialized guard rail requirements, CAD/CAM technology enables parametric modeling of terminal transitions and anchor assemblies compliant with regional safety regulations. Material traceability protocols document each production stage, guaranteeing that structural certificates provide validated evidence of compliance. These capabilities permit structural engineers to overcome site-specific constraints through purpose-engineered solutions.

Global Implementation Case Studies

The Øresund Bridge connecting Denmark and Sweden utilized over 8,200 tonnes of custom IPE beam sections to support its railway platform infrastructure. Engineering analysis confirmed that the selected profiles reduced vibration transmission by 42% compared to conventional alternatives. In earthquake-prone regions, Japan's latest Shinkansen rail expansions incorporated seismic-resistant metal beam guard rail assemblies capable of maintaining structural integrity at 0.7g ground acceleration. Aviation projects demonstrate another application: the Singapore Airport expansion employed hollow steel beam elements spanning terminal structures where integrated cable routing reduced electrical installation time by 35%. Such implementations validate these systems across complex structural scenarios.

Future-Proof Infrastructure with IPE Beam Systems

The continuous development of IPE beam technologies addresses emerging structural challenges posed by climate adaptation requirements. Advanced weathering steel formulations now provide maintenance-free service lives exceeding 45 years without protective coatings. The integration possibilities with complementary metal beam guard rail systems deliver comprehensive infrastructure safety that adapts to changing transportation needs. Modern specifications increasingly emphasize life cycle efficiency, where optimized hollow steel beam designs demonstrate tangible operational advantages through reduced energy requirements during fabrication and installation. These advancements position structural steel systems as indispensable components for resilient, adaptable, and sustainable construction worldwide.

(ipe beam)

FAQS on ipe beam

Q: What is an IPE beam commonly used for?

A: An IPE beam is a standardized I-shaped steel beam used in construction for load-bearing structures like roofs, floors, and bridges. Its tapered flanges and consistent profile ensure high strength-to-weight efficiency. It is widely preferred in European building projects.

Q: How does a metal beam guard rail enhance safety?

A: Metal beam guard rails, often made from steel, absorb impact energy during collisions to protect vehicles and pedestrians. Their durable design ensures longevity in highways and industrial zones. They meet strict safety standards for crash resistance.

Q: What are the advantages of hollow steel beams?

A: Hollow steel beams offer reduced weight while maintaining structural integrity, ideal for frameworks requiring material efficiency. Their hollow core allows utilities like wiring or plumbing to pass through. They are cost-effective for large-scale architectural projects.

Q: Can IPE beams be combined with hollow steel beams?

A: Yes, IPE beams and hollow steel beams are often integrated in hybrid structures to optimize load distribution and space usage. This combination balances strength and flexibility in complex designs. Engineers tailor such mixes for bridges or multi-story buildings.

Q: How do metal beam guard rails differ from IPE beams?

A: Metal beam guard rails prioritize impact absorption and roadside safety, whereas IPE beams focus on structural support in construction. Guard rails have specific crash-test certifications, while IPE beams adhere to dimensional and load-capacity standards. Their applications rarely overlap.

Products Categories

Latest News

-

Revolutionize Industrial Coating with Automated Spray Painting Machine

NewsApr.03,2025 -

Maximize Efficiency with Advanced Container Lifting Equipment

NewsApr.03,2025 -

Maximize Efficiency and Precision with Automated Spray Painting Machine

NewsApr.03,2025 -

Enhance Efficiency and Safety with Advanced Container Lifting Equipment

NewsApr.03,2025 -

Enhance Coating Efficiency with Advanced Automated Spray Painting Machine

NewsApr.03,2025 -

Elevate Coating Precision with Automated Spray Painting Machine

NewsApr.03,2025 -

Achieve Unmatched Coating Precision with Automated Spray Painting Machine

NewsApr.03,2025