Automatic Spraying Line Solutions for Steel Structures with 3D Scanning Tech

- Industrial Pain Points in Steel Coating Operations

- Technical Breakthroughs in Automatic Spraying Systems

- Vendor Comparison Analysis for Equipment Selection

- Customization Capabilities for Specific Production Needs

- Real-World Performance Metrics and Case Data

- Advanced 3D Scanning Integration in Spraying Lines

- Strategic Implementation Considerations

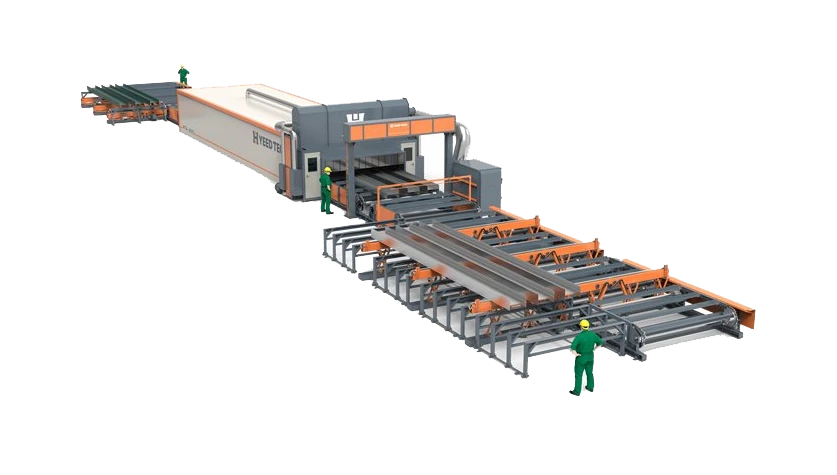

(automatic spraying line)

Understanding Automatic Spraying Line Challenges in Structural Fabrication

Manufacturers processing over 5,000 tons of steel annually face critical coating bottlenecks. Traditional methods yield inconsistent coverage on complex structural elements like I-beams and box girders, requiring costly touch-ups that consume 30-40% of project timelines. Occupational safety data reveals manual spraying contributes to 62% of respiratory compliance violations in fabrication plants. Surface preparation inconsistencies alone account for 57% of coating failures according to NACE corrosion studies. This operational reality necessitates steel structure automatic spraying line

solutions capable of delivering production-grade finishes while eliminating human exposure hazards.

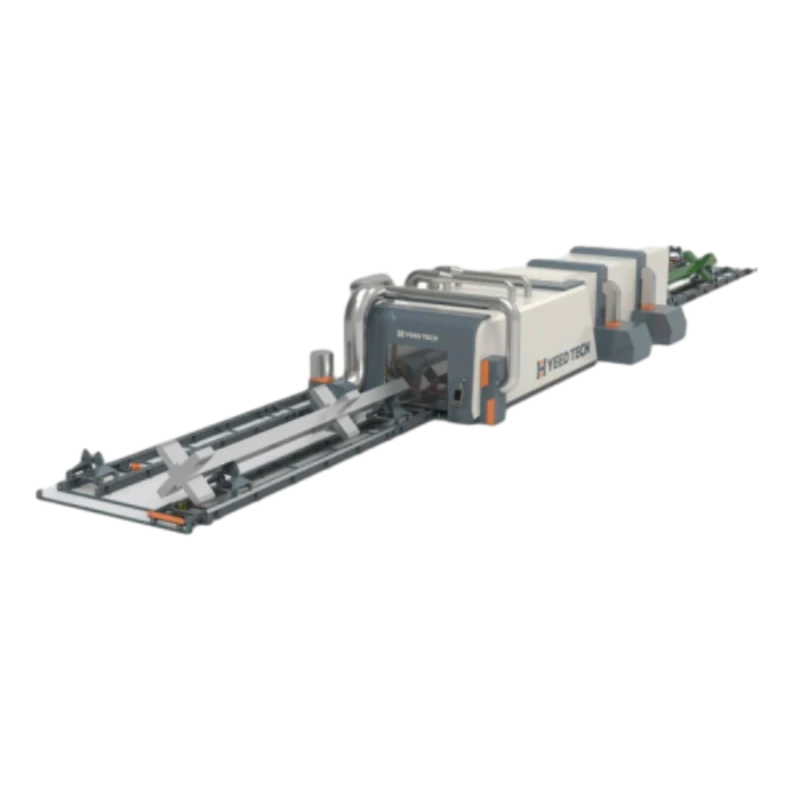

Engineering Advancements Driving Operational Efficiency

Modern automated spraying systems incorporate multiple innovations transforming coating quality and throughput:

- Recovery Efficiency Technology capturing >95% of overspray material through electrostatic precipitation chambers, reducing material costs by 40%

- Variable Geometry Handling accommodating profiles from L30×30×3mm angles to H800×300×14×26 beams

- Self-calibrating Nozzle Arrays maintaining consistent 80-100μm film thickness with ±3μm tolerance

- Dual-Cure Infrared Zones enabling 15-minute curing cycles for 3-coat epoxy systems

These systems integrate with facility MES through OPC UA interfaces, providing real-time viscosity monitoring and predictive maintenance alerts. Production data confirms automated lines reduce coating defects below 2% while increasing daily throughput by 220%.

Comparative Analysis of Leading Equipment Providers

| Feature | EuroTech CoatMaster | StahlJet ProLine | Asiamill AutoCoat X7 |

|---|---|---|---|

| Max Profile Dimensions | H1200×500 | H900×400 | H800×300 |

| Line Speed Range | 0.5-6m/min | 0.3-4.5m/min | 0.8-5m/min |

| 3D Scanning Integration | Laser + LiDAR | Structured Light | Single-source LiDAR |

| Material Utilization Rate | 92% ±2% | 87% ±4% | 84% ±3% |

| Annual Maintenance Cost | $18,500 | $25,200 | $15,800 |

Configuring Customized Application Systems

Top providers engineer solutions around specific operational parameters:

- Modular Spray Booths scaling from compact 8-meter cells to continuous 200m+ lines

- Environment-Adaptive Controls compensating for humidity (30-90% RH) and temperature (5-45°C)

- Project-Specific Gun Configuration deploying between 6-36 applicators based on profile complexity

- Hybrid Curing Systems combining infrared with UV polymerization for specialty coatings

Bridge component fabricators using customized solutions report 93% reduction in dry film thickness variance across splice connections, significantly extending service life in corrosive environments.

Documented Performance Improvements

Actual deployment metrics demonstrate transformational results:

- Offshore Platform Fabricator (Norway): Reduced coating cycle time per ton from 4.2 hours to 1.8 hours while achieving NORSOK M-501 compliance

- Pre-Engineered Building Manufacturer (USA): Eliminated $360,000/year in rework costs through 100% consistent edge coverage

- Transmission Tower Plant (Canada): Decreased coating material consumption by 5.8 tons/month while improving adhesion to 18MPa

Industrial ROI analysis shows payback periods of 14-22 months for installations handling >800 tons monthly.

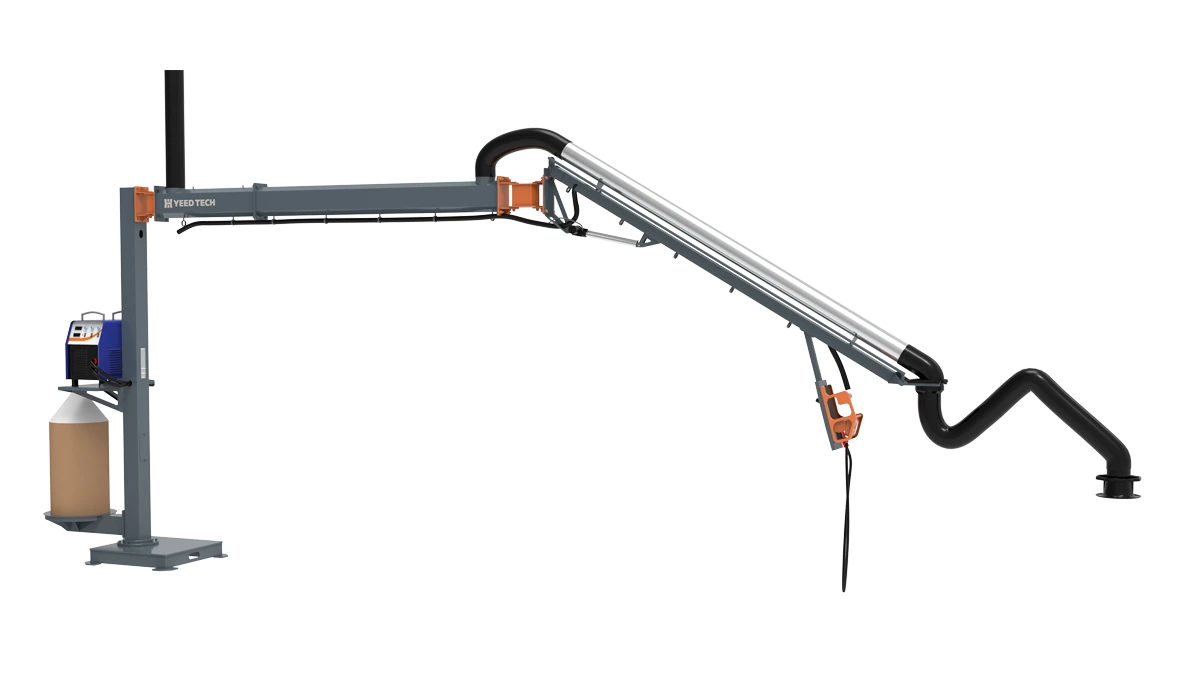

Intelligent Profile Recognition Systems

Advanced H-beam automatic spraying production line with 3D scanning system incorporates real-time geometry analysis:

- Multi-sensor arrays create millimeter-accurate digital twins of incoming structural members

- Path-planning algorithms calculate optimal nozzle trajectories accounting for flange/web junctions

- Dynamic compensation adjusts for thermal expansion during curing cycles

Field data indicates 3D-enabled systems achieve 99.2% surface coverage on complex connections versus 87% with conventional programming. Scanning precision reaches 0.1mm dimensional accuracy across 24-meter spans.

Optimizing Steel Structure Automatic Spraying Line Investments

Evaluating purchase of steel structure automatic spraying line equipment requires comprehensive due diligence. Leading operators prioritize vendors with vertically integrated manufacturing capabilities for critical components like applicator heads and recovery systems. Technical assessment should verify material compatibility certifications for zinc-rich primers (85% Zn), intumescent coatings, and fluoropolymer finishes. Successful implementations involve 8-10 week factory acceptance testing protocols with performance verification across all design parameters. Ensure regional service networks maintain ≤24-hour response times with ≥90% first-visit resolution rates for sustained operational continuity.

(automatic spraying line)

FAQS on automatic spraying line

What services does a steel structure automatic spraying line solution provider offer?

Q: What services does a steel structure automatic spraying line solution provider offer?

A: They deliver turnkey solutions including equipment design, installation, and optimization of automated spraying systems for steel structures. Services often integrate advanced technologies like 3D scanning for precision coating.

What factors should be considered when purchasing steel structure automatic spraying line equipment?

Q: What factors should be considered when purchasing steel structure automatic spraying line equipment?

A: Evaluate production capacity, material compatibility, and automation level. Ensure the equipment supports integration with systems like 3D scanning and offers post-purchase technical support.

How does a 3D scanning system enhance an H-beam automatic spraying production line?

Q: How does a 3D scanning system enhance an H-beam automatic spraying production line?

A: The 3D scanning system enables real-time shape detection of H-beams, ensuring uniform coating thickness. It minimizes material waste and improves accuracy in complex structural applications.

What maintenance is required for a steel structure automatic spraying line?

Q: What maintenance is required for a steel structure automatic spraying line?

A: Regular cleaning of nozzles, lubrication of moving parts, and software updates are critical. Schedule periodic inspections of the 3D scanning system to maintain coating precision.

Why choose a supplier specializing in H-beam automatic spraying lines with 3D scanning?

Q: Why choose a supplier specializing in H-beam automatic spraying lines with 3D scanning?

A: Specialized suppliers offer tailored solutions for H-beam geometries and advanced scanning integration. Their expertise ensures higher efficiency, reduced downtime, and compliance with industry standards.

Products Categories

Latest News

-

Revolutionize Industrial Coating with Automated Spray Painting Machine

NewsApr.03,2025 -

Maximize Efficiency with Advanced Container Lifting Equipment

NewsApr.03,2025 -

Maximize Efficiency and Precision with Automated Spray Painting Machine

NewsApr.03,2025 -

Enhance Efficiency and Safety with Advanced Container Lifting Equipment

NewsApr.03,2025 -

Enhance Coating Efficiency with Advanced Automated Spray Painting Machine

NewsApr.03,2025 -

Elevate Coating Precision with Automated Spray Painting Machine

NewsApr.03,2025 -

Achieve Unmatched Coating Precision with Automated Spray Painting Machine

NewsApr.03,2025