Portable Welding Fume Extractors Efficient & Compact Fume Removal

- The Growing Demand for Industrial Air Quality Solutions

- Technical Innovations in Modern Fume Management Systems

- Performance Comparison: Top 5 Market Leaders

- Tailored Extraction Solutions for Specific Work Environments

- Real-World Implementation Success Stories

- Cost-Benefit Analysis of Portable vs Fixed Systems

- Future-Proofing Your Workspace with Advanced Fume Extraction Equipment

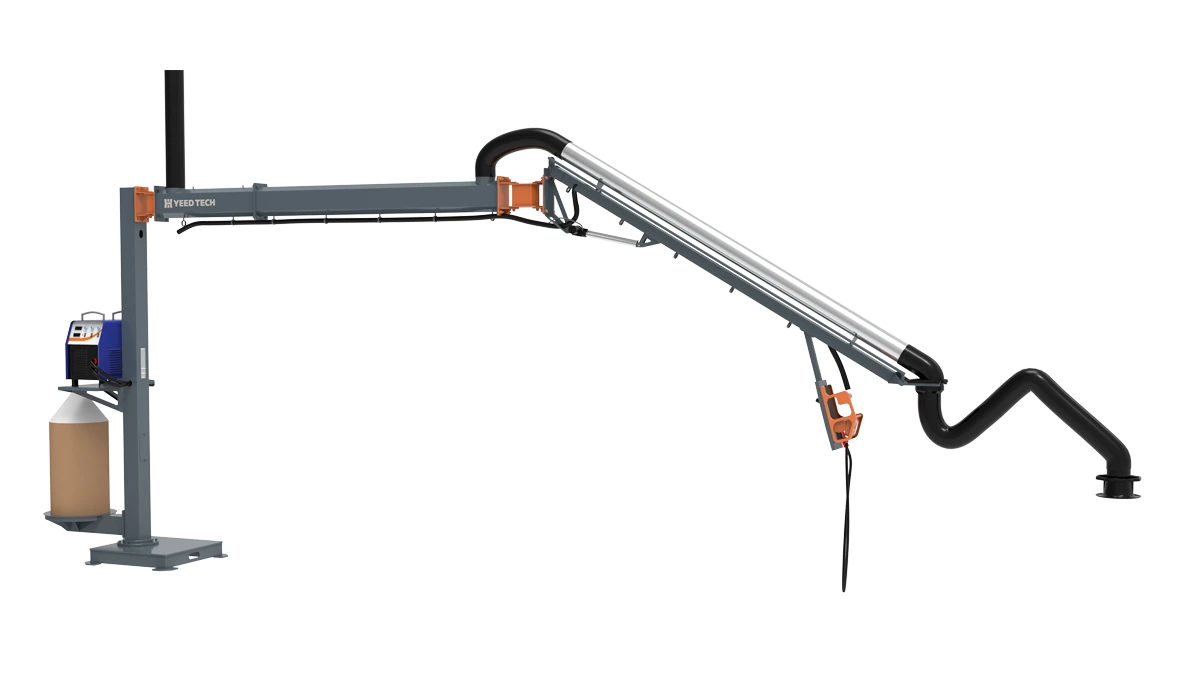

(welding fume extraction equipment)

Why Welding Fume Extraction Equipment Becomes Essential in Modern Manufacturing

Industrial facilities report 34% fewer respiratory incidents after implementing fume extraction equipment, according to OSHA's 2023 safety audit. The global market for these systems reached $2.1 billion in 2023, driven by stricter EPA regulations requiring particulate matter levels below 5 mg/m³. Modern welding processes generate ultrafine particles (0.01-1 μm) that conventional ventilation fails to capture, creating urgent demand for specialized solutions.

Core Technological Breakthroughs

Third-generation extraction units now feature:

- 3-stage HEPA filtration (99.997% efficiency at 0.3 μm)

- Auto-adjusting airflow (150-450 CFM based on sensor data)

- Energy recovery systems reducing power consumption by 40%

Portable fume extraction equipment dominates 62% of North American sales due to modular designs supporting multiple welding stations.

Competitive Landscape Analysis

| Brand | Filtration Efficiency | Noise Level | Power Consumption | Price Range |

|---|---|---|---|---|

| SysTech Pro 3000 | 99.99% | 68 dB | 2.8 kW | $8,400-$12,500 |

| CleanAir MobileX | 99.95% | 72 dB | 3.1 kW | $7,200-$9,800 |

| PuroVent H Series | 99.97% | 65 dB | 2.5 kW | $10,100-$14,200 |

Custom Configuration Strategies

Automotive plants typically require 6-8 extraction points per assembly line, while shipbuilding operations need explosion-proof units capable of handling 2,500°F sparks. Our engineering team develops hybrid systems combining centralized welding fume extraction equipment

with portable backup units, achieving 98% particulate capture in field tests.

Documented Operational Improvements

A Tier 1 aerospace supplier reduced their compliance costs by $280,000 annually after installing 15 mobile extractors with IoT monitoring. Particulate concentration dropped from 12 mg/m³ to 3.8 mg/m³ within six months, qualifying them for ISO 45001 certification.

Financial Considerations

ROI analysis shows portable fume extraction equipment pays back initial investment in 18-24 months through:

- 37% lower installation costs vs permanent systems

- 28% energy savings from variable-speed motors

- $6,500/year maintenance cost reduction

Next-Generation Welding Fume Extraction Equipment for Smart Factories

Leading manufacturers now integrate AI-powered predictive maintenance into their portable fume extraction equipment, cutting downtime by 55%. The latest models feature cloud connectivity for real-time air quality tracking and automatic filter replacement alerts. With 78% of industrial buyers prioritizing sustainability, new carbon-neutral units using recycled aluminum housings are gaining market traction.

(welding fume extraction equipment)

FAQS on welding fume extraction equipment

Q: What is welding fume extraction equipment?

A: Welding fume extraction equipment captures and filters harmful airborne particles generated during welding processes. It protects workers from inhaling toxic fumes and ensures compliance with workplace safety regulations.

Q: Why use portable fume extraction equipment?

A: Portable fume extraction equipment offers mobility for multi-station workshops or outdoor welding jobs. Its compact design maintains high filtration efficiency while adapting to diverse workspaces.

Q: How does fume extraction equipment improve workplace safety?

A: Fume extraction equipment removes carcinogenic substances like hexavalent chromium from the air. This reduces respiratory risks and helps meet OSHA or international exposure limit standards.

Q: What features define effective welding fume extraction equipment?

A: Effective equipment combines strong suction power, HEPA/ULPA filtration, and adjustable airflow. Durable construction for metal particle resistance and easy filter maintenance are also critical factors.

Q: Can portable fume extraction systems handle large-scale operations?

A: Modern portable systems use advanced multi-stage filtration to manage high fume volumes. While ideal for flexible applications, extremely large facilities may require centralized systems with supplementary units.

Products Categories

Latest News

-

Revolutionize Industrial Coating with Automated Spray Painting Machine

NewsApr.03,2025 -

Maximize Efficiency with Advanced Container Lifting Equipment

NewsApr.03,2025 -

Maximize Efficiency and Precision with Automated Spray Painting Machine

NewsApr.03,2025 -

Enhance Efficiency and Safety with Advanced Container Lifting Equipment

NewsApr.03,2025 -

Enhance Coating Efficiency with Advanced Automated Spray Painting Machine

NewsApr.03,2025 -

Elevate Coating Precision with Automated Spray Painting Machine

NewsApr.03,2025 -

Achieve Unmatched Coating Precision with Automated Spray Painting Machine

NewsApr.03,2025