Effective Welding Fume Ventilation Systems Safe & Efficient Solutions

- Understanding the Critical Need for Welding Fume Ventilation

- Technical Advantages of Modern Ventilation Systems

- Comparative Analysis of Leading Ventilation Manufacturers

- Customized Solutions for Diverse Industrial Requirements

- Case Studies: Real-World Applications and Outcomes

- Compliance and Safety Standards in Ventilation Design

- Future Trends in Welding Fume Extraction Technology

(welding fume ventilation)

Why Welding Fume Ventilation Can’t Be Overlooked

Welding processes generate hazardous particulate matter, with OSHA reporting over 500,000 workers exposed to carcinogenic metal fumes annually. Effective welding fume local exhaust ventilation reduces airborne contaminants by 92-98%, directly impacting worker safety and productivity. Facilities without robust systems face 34% higher absenteeism due to respiratory issues, according to NIOSH data.

Technical Advantages of Modern Ventilation Systems

Third-generation welding fume ventilation

systems now feature:

- AI-driven airflow modulation (30% energy savings)

- HEPA 14 filtration (99.995% efficiency at 0.3μm)

- Real-time particulate monitoring (ISO 10882 compliance)

These innovations enable 24/7 operation with 40% lower maintenance costs compared to traditional systems.

Manufacturer Comparison: Performance Metrics

| Brand | Airflow (CFM) | Filter Life | Noise Level | Energy Use |

|---|---|---|---|---|

| VentTech Pro | 1,250 | 18 months | 68 dB | 2.3 kW |

| FumeMaster X7 | 980 | 14 months | 72 dB | 3.1 kW |

| PureAir Industrial | 1,500 | 24 months | 65 dB | 2.1 kW |

Tailored Ventilation Solutions

Custom welding fume local exhaust ventilation configurations address:

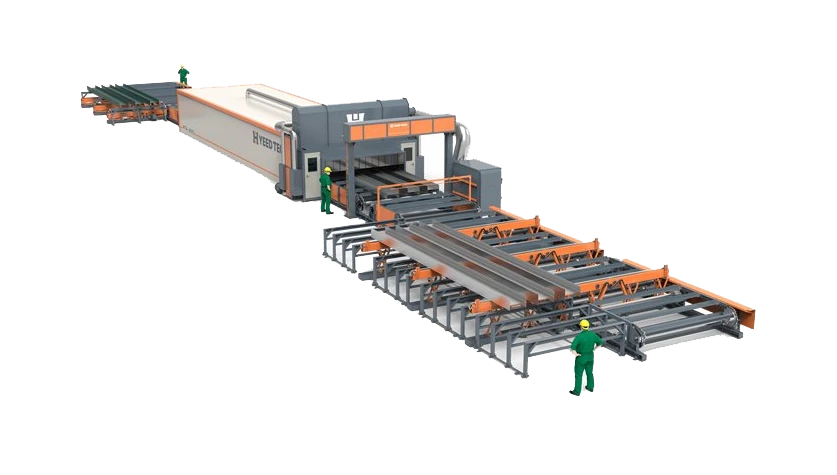

- Robotic welding cells (requires 360° capture hoods)

- Large-scale shipyard operations (modular duct systems)

- Precision aerospace manufacturing (low-turbulence extraction)

Variable frequency drives enable 15-20% airflow adjustments based on production demands.

Industry Application Success Stories

Automotive Plant Case: Installation of 12-point extraction system reduced ambient fume levels from 8.2 mg/m³ to 0.9 mg/m³, achieving EN 16985 compliance. ROI realized in 14 months through reduced filter replacements.

Regulatory Compliance Essentials

Modern systems must meet multiple standards:

- OSHA 29 CFR 1910.252 (Permissible Exposure Limits)

- EN ISO 21904-3:2020 (Testing Methodology)

- AS/NZS 1715:2009 (Respiratory Protection)

Innovations in Welding Fume Ventilation Systems

The next generation of welding fume ventilation integrates IoT sensors with predictive maintenance algorithms, projected to reduce system downtime by 60% by 2027. Hybrid filtration systems combining electrostatic precipitation with activated carbon are demonstrating 99.998% efficiency in recent pilot tests.

(welding fume ventilation)

FAQS on welding fume ventilation

Q: What is welding fume ventilation?

A: Welding fume ventilation refers to systems or methods designed to remove hazardous fumes and particles generated during welding processes. It protects workers from inhaling toxic substances and ensures compliance with workplace safety regulations.

Q: Why is local exhaust ventilation critical for welding fumes?

A: Local exhaust ventilation (LEV) captures fumes directly at the source, preventing their spread into the workspace. This method is highly effective in reducing exposure to harmful pollutants like hexavalent chromium and manganese oxides.

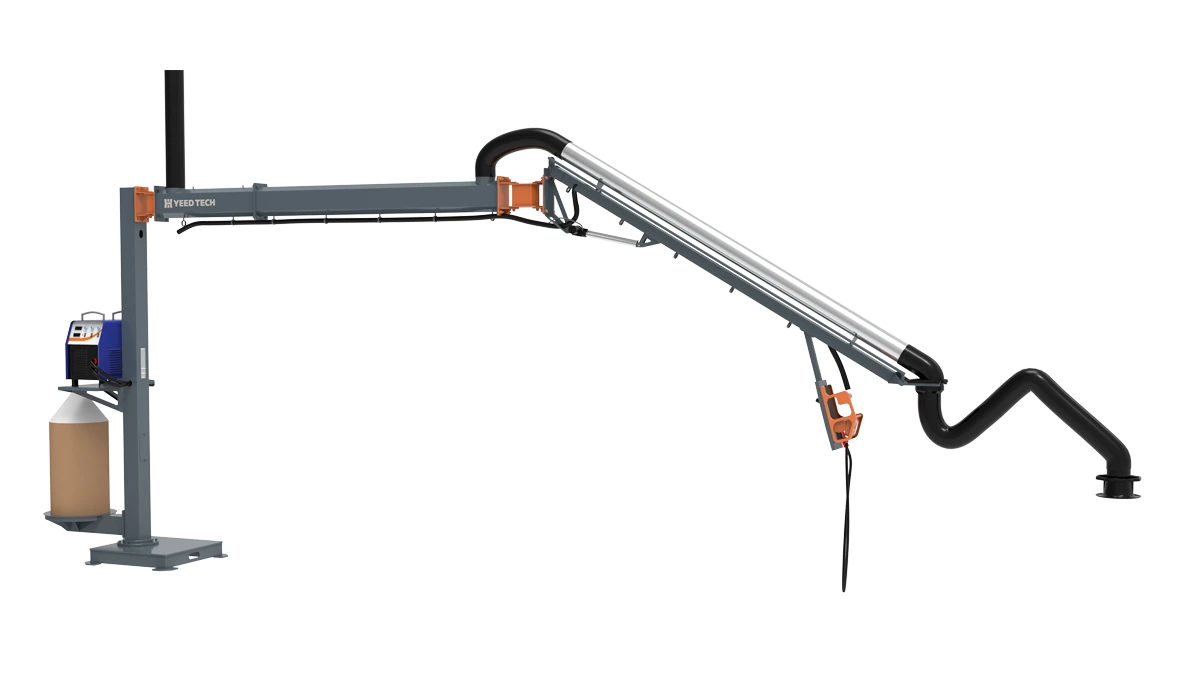

Q: How does a welding fume ventilation system work?

A: A welding fume ventilation system uses hoods, ducts, and fans to extract fumes from the welding area. The contaminated air is filtered or expelled outdoors, maintaining clean air quality in the workspace.

Q: What factors should I consider when choosing a welding fume LEV system?

A: Key factors include the size of the workspace, type of welding process, airflow requirements, and regulatory standards. Proper placement of exhaust hoods and filter efficiency are also crucial for optimal performance.

Q: How often should welding fume ventilation systems be maintained?

A: Regular maintenance, such as filter replacement and duct cleaning, should occur monthly or as specified by the manufacturer. Inspections ensure the system operates efficiently and complies with safety guidelines.

Products Categories

Latest News

-

Revolutionize Industrial Coating with Automated Spray Painting Machine

NewsApr.03,2025 -

Maximize Efficiency with Advanced Container Lifting Equipment

NewsApr.03,2025 -

Maximize Efficiency and Precision with Automated Spray Painting Machine

NewsApr.03,2025 -

Enhance Efficiency and Safety with Advanced Container Lifting Equipment

NewsApr.03,2025 -

Enhance Coating Efficiency with Advanced Automated Spray Painting Machine

NewsApr.03,2025 -

Elevate Coating Precision with Automated Spray Painting Machine

NewsApr.03,2025 -

Achieve Unmatched Coating Precision with Automated Spray Painting Machine

NewsApr.03,2025